Our Solutions

Custom R&D Solutions

Ginkgo.Your Innovation Partner.

Our Solutions

Custom R&D Solutions

Custom R&D Solutions

Custom R&D Solutions

When shifting from plant-based extraction to a fermentation-based production to scale to global demand for their nutraceutical, our partner encountered an enzymatic bottleneck in engineering their yeast host.

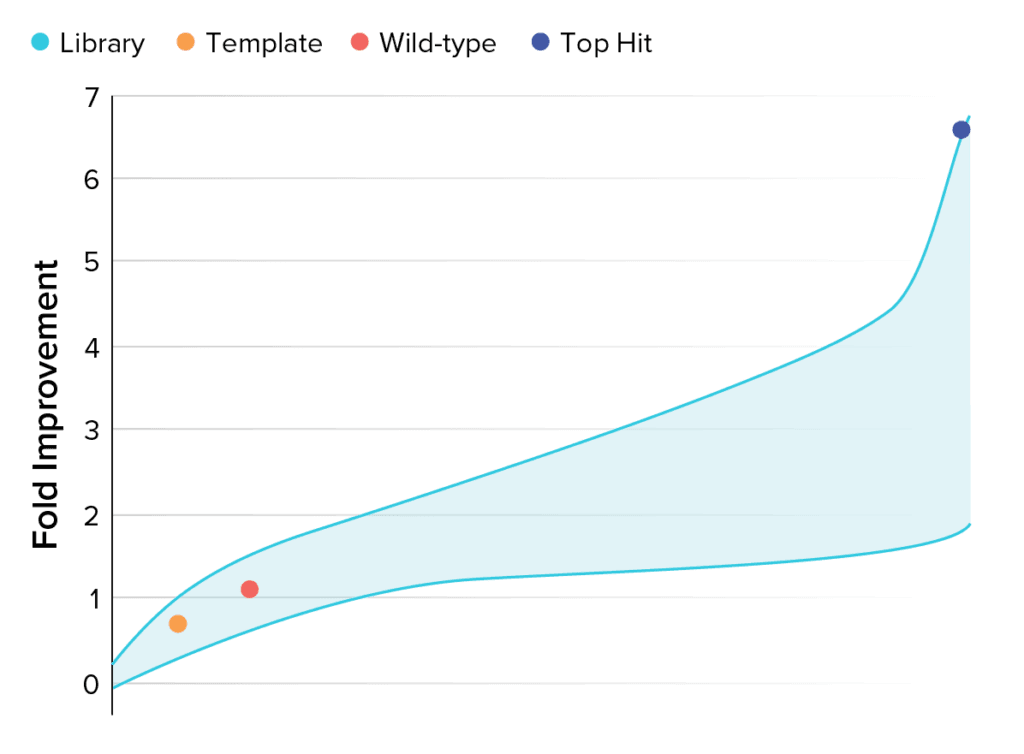

Ginkgo Bioworks’ Enzyme Intelligence suite of tools, equipped with AI-guided design and a vast proprietary protein database, engineered an enzyme achieving over 600% performance improvement. This leap in enzyme activity enabled our partner to establish sustainable and efficient production through fermentation, allowing them to meet their market demand.

A nutraceutical company partnered with Ginkgo Bioworks because they needed to shift their production from plant-extraction to fermentation, thereby lowering cost of production and allowing them to scale production to meet global demand.

Our work started with Metagenomic Sourcing to identify alternatives to the natural enzyme that was a bottleneck in production

We leveraged Protein Engineering to develop chimeric proteins from the metagenomic campaign with increased function.

Ginkgo’s protein engineering team identified enzymes with 600% increase in activity compared to the native starting protein.

As a result of our engineering, the collaboration developed a yeast strain with high titers of our partner’s target molecules. Our approach achieved a significant cost reduction and increased efficiency in their production, enabling them to scale production to meet global demand.

To meet the challenges with inefficient production of their molecule from plants and to reduce production costs, our partner sought to switch from traditional plant extractions to synthesizing them in yeast, using the power of fermentation. Together, we identified biological pathways capable of producing these rare molecules in large quantities. However, one enzyme from the original plant pathway was a bottleneck in yeast. To overcome this, our partner utilized Ginkgo’s Enzyme Intelligence suite of engineering tools to optimize production of this enzyme so as to meet their production targets.

We searched for natural equivalents of the bottleneck enzyme through metagenomic analysis, identifying homologs in Ginkgo’s proprietary database of more than 2 billion genes. However, although some of these display increased activity, none of the homologs passed the required threshold. We developed a Protein Engineering campaign to develop sequences with a high probability of function.

Our engineers developed a combinatorial library based on these homologs, using sequence-based statistical models for sequence redesign and scanning mutagenesis of the native enzyme.

This 3,000-member library was subjected to screening in our yeast host for enzymes with increased activity.

We iterated on this initial library and carried forward our learnings into additional rounds of protein engineering.

After five cycles of engineering, we identified a sequence that had over 600% improvement in activity. This enzyme showed <80% sequence identity to the original sequence.

Our identification of this key enzyme provided a strategic pathway for our partner to carve a unique space and meet demand through fermentation. They expanded their project with us further to achieve their production goals.

Ginkgo’s initial success led to an expansion of the project to take our partner’s proof-of-concept to commercial product.

Ginkgo’s engineers continued Strain Improvement on their initial strain, further optimizing their biosynthesis pathway. Throughout the project, we screened over 19,000 enzymes across the entire pathway to develop their commercial production strain.

In the final stages of strain engineering, Ginkgo started Fermentation and Downstream Processing to make certain that the strain we were developing could be transferred to production facilities so our partner could hit the ground running.

Our final piece of work was completing a Technology Transfer to our partner’s production facility. We verified that our strain and process functioned at scale, leaving our partner with peace of mind as they grew production to meet global demand.

Ginkgo Bioworks’ Enzyme Intelligence suite of tools enables our partners to achieve their production goals through biology. turns significant technical challenges into opportunities. We work with our partners to optimize pathways to produce their target small molecules production processes. We encourage potential partners to discover how our tools and expertise can elevate your projects, lower costs, and enhance sustainability. Shape the future of biotechnology and drug development with us—contact us to begin exploring revolutionary solutions.